Balli Steel, a leading international steel trader, has reported that despite the slowdown in the global economy, the role of steel in construction industry markets across the world will grow. Balli Steel highlight that this growth is due to a range of factors including environmental and recycling benefits, urbanisation, technological advances and the load bearing, high rise opportunities, safety and speed of construction benefits that steel provides.

Company forecasts indicate that global annualised steel production this year is to be 1.1 billion tonnes, with the construction industry being the largest end-user of steel, accounting for over 40% of total steel consumption.

Balli Steel calculate that the competitive cost gap between steel and concrete building frames is widening. A recent report by the British Constructional Steel Association (Q4 2008) showed a £22.22 per sqm advantage for steel frames over concrete, up from £12.10 per sqm in 1995.

Another advantage is that whilst steel has a higher embodied carbon value per tonne than concrete, a tonne of steel goes a lot further so steel structures generally have a lower carbon footprint than concrete ones.

Vahid Alaghband, Group Chairman of Balli Steel, said: “Whilst many people may often equate steel buildings and infrastructure schemes with super-high rise and large span structures, steel is also used extensively in small scale and low rise buildings. Steel is used throughout the construction industry and the building process, not just on mega projects.”

Balli Steel points to the global process of urbanisation as another factor driving the demand for new buildings, and therefore a demand for construction steel. The United Nation’s (UN) latest figures show that 50% of the world’s population live in urban areas. Over 3.2 billion people now live in cities, up from 732 million in 1950. The UN calculates that by 2050, over 6 billion people, 75% of humanity, will be living in towns and cities.

In the current ecologically aware times, steel is often favoured over other materials like wood and plastic. Nasser Alaghband, Managing Director of Balli steel commented: “The advantages of steel in the building construction process include strength, energy efficiency, design flexibility, fire resistance, speed of assembly, material cost advantage and less maintenance. The steel industry has been actively recycling for more than 150 years and it is becoming increasingly financially and environmentally advantageous to continue with this approach. It is cheaper to recycle steel than to mine iron ore and manipulate it through the production process to form new steel.”

Over 95% of structural steel beams and plates, used in building manufacture, are recycled, and similarly, other construction industry elements such as reinforced bars are recycled at a rate of around 65%. Balli highlight that the energy saved by recycling these large amounts of steel globally is enough to power 18 million homes around the world for one year.

About Balli Holdings

Balli Holdings, is a large private, multi-national corporation, headquartered in London, but with offices in Dubai and other key business hubs around the world. Balli was established in 1982 and operates a number of affiliated companies specialising in commodity trading, industrial, real estate and private equity with operations in over 20 countries. Together with its affiliated companies, Balli employ over 2,000 people worldwide.

Balli Steel is the company’s principal operating subsidiary, and is one of the largest independent steel trading companies in the world. Balli Steel provides raw materials and steel to a number of market segments including steel mills, steel service centres, pipe and tube makers, the oil and gas industry and other designated end user segments such as the packaging products industry.

Via EPR Network

More Industrial press releases

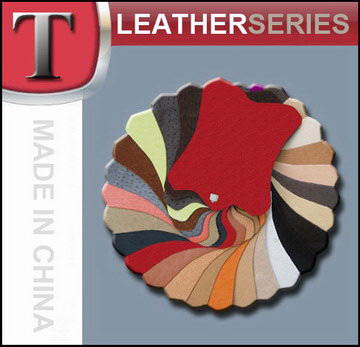

Due to the financial crisis, the export of leather has not been doing very well this year. The export value has decreased for the first time over the last 10 years. Some Chinese tanneries have to cut cost or scale down their production in order to get through the crisis, waiting for a comeback of international market demand very soon.

Due to the financial crisis, the export of leather has not been doing very well this year. The export value has decreased for the first time over the last 10 years. Some Chinese tanneries have to cut cost or scale down their production in order to get through the crisis, waiting for a comeback of international market demand very soon.